Solução de Robô de Fundição Abb

Solução de robô de fundição Abb:

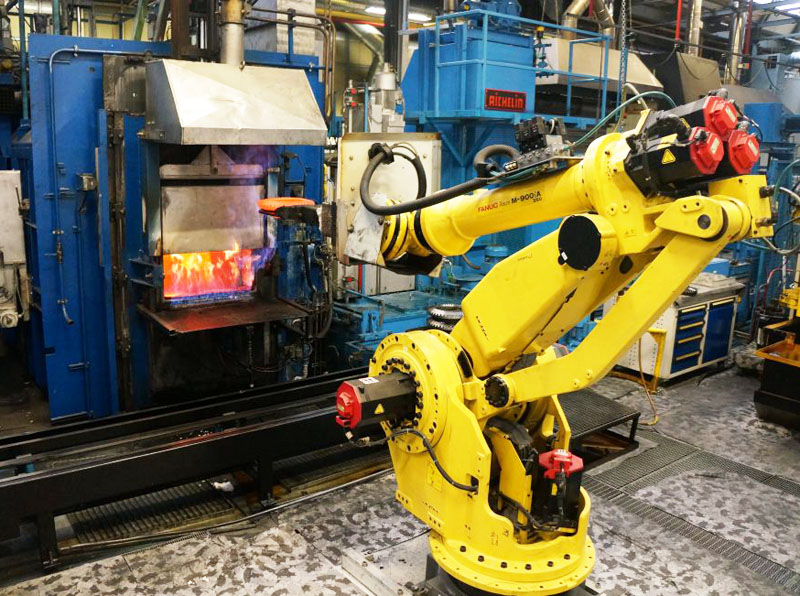

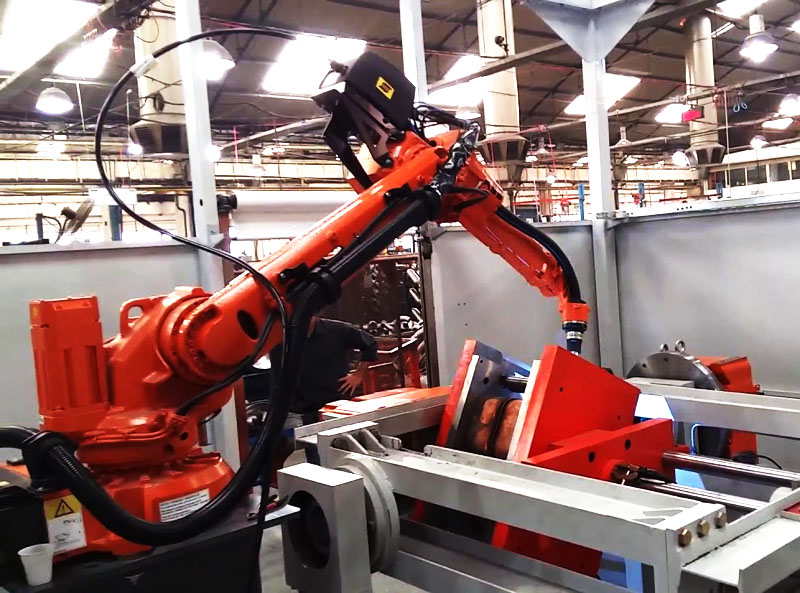

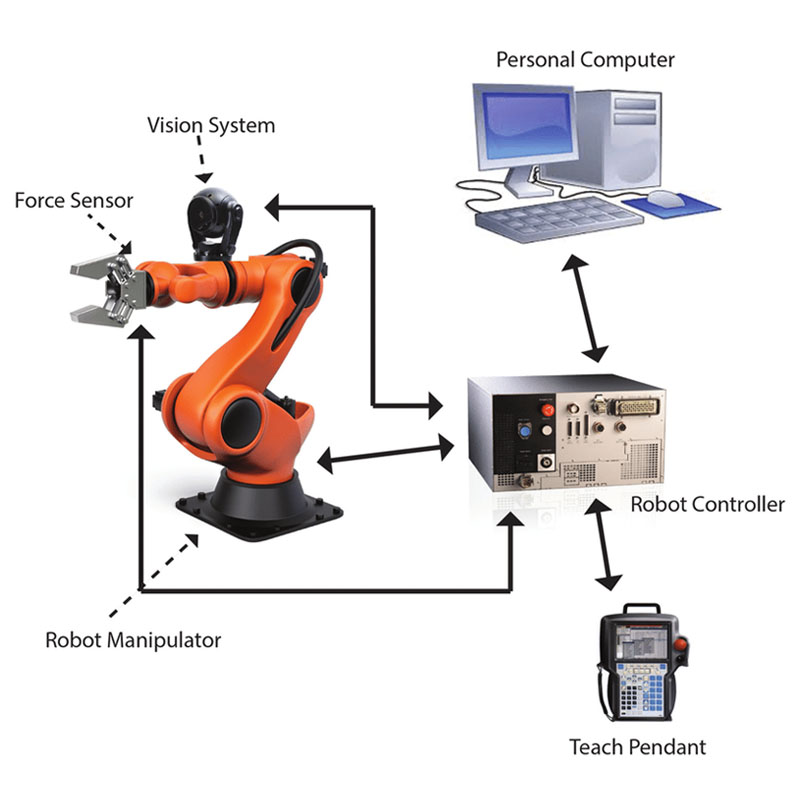

1, Capacidades avançadas de automação: Os robôs de fundição da ABB estão equipados com capacidades avançadas de automação, permitindo-lhes lidar com tarefas complexas com precisão e exatidão. Eles podem realizar tarefas como vazar metal fundido, manusear componentes pesados e manipular moldes com facilidade.

2, Maior segurança do trabalhador: Os robôs de fundição da ABB ajudam a minimizar o risco para os trabalhadores humanos em ambientes de fundição perigosos. Eles podem realizar tarefas em temperaturas extremas, trabalhar em espaços confinados e manusear cargas pesadas, reduzindo a probabilidade de acidentes e lesões.

3, Maior produtividade e eficiência: Os robôs de fundição da ABB melhoram muito a produtividade nas operações de fundição. Eles podem trabalhar continuamente sem interrupções, levando ao aumento das taxas de produção e à redução dos tempos de ciclo. Seus movimentos rápidos e precisos permitem um fluxo de trabalho eficiente e otimizado na fundição.

Entre em contato conosco para obter parâmetros técnicos detalhados.

Solução de robô de fundição Abb:

Os robôs de fundição da ABB são usados principalmente em indústrias para tarefas como manuseio de materiais, atendimento de máquinas, fundição, fundição sob pressão e soldagem por pontos. Eles são projetados para resistir a ambientes agressivos e de alta temperatura. Esses robôs aumentam a produtividade, melhoram a qualidade e aumentam a segurança no local de trabalho. Eles também são usados na indústria automotiva para tarefas como montagem, pintura e soldagem. Os robôs de fundição da ABB também são capazes de realizar tarefas mais complexas, como impressão 3D, com precisão e exatidão. Eles são projetados para serem flexíveis e versáteis para se adaptarem a uma variedade de aplicações industriais.