Solução de robótica em fundição

Solução de robótica em fundição:

1, Maior eficiência: A robótica em fundições pode melhorar muito a eficiência, automatizando tarefas como manuseio de materiais, vazamento e acabamento. Os robôs podem trabalhar em um ritmo consistente, sem interrupções ou fadiga, levando a uma produção mais rápida e a tempos de ciclo reduzidos.

2, Maior segurança do trabalhador: As operações de fundição podem ser perigosas, expondo os trabalhadores a altas temperaturas, equipamentos pesados e materiais perigosos. A utilização de robôs na indústria de fundição pode ajudar a minimizar esses riscos ao realizar tarefas perigosas, reduzindo a probabilidade de acidentes e lesões aos trabalhadores humanos.

3, Precisão e exatidão aprimoradas: Robôs em fundições podem executar tarefas com um alto nível de precisão e exatidão. Eles podem despejar metal fundido em moldes com precisão, manusear e posicionar peças de maneira consistente e realizar tarefas de acabamento complexas. Isso resulta em melhor qualidade de fundição e reduz o risco de defeitos ou inconsistências.

Entre em contato conosco para obter parâmetros técnicos detalhados.

Solução de robótica em fundição:

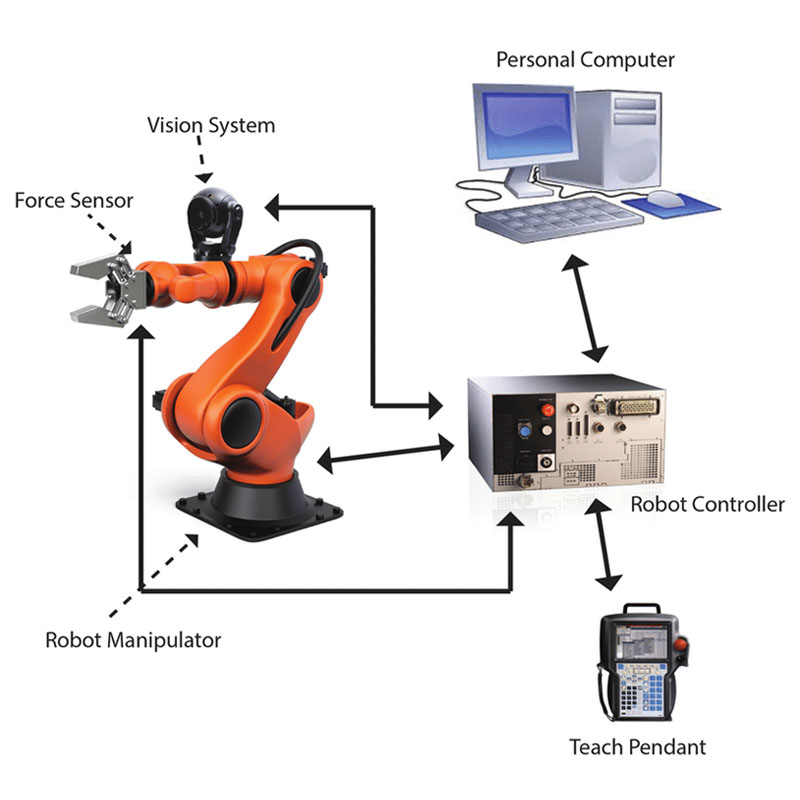

A robótica em aplicações de fundição revolucionou a indústria de manufatura. Solução de robótica em fundição em nossa empresa pode economize 92% no custo de uma patrulha tripulada. Entre em contato conosco para obter parâmetros técnicos detalhados. Os robôs são usados para tarefas como fundição, moldagem e acabamento, reduzindo o envolvimento humano e aumentando a eficiência e a precisão. Eles podem suportar condições adversas, incluindo altas temperaturas e poeira, garantindo qualidade de produção consistente. Os robôs também aumentam a segurança ao realizar tarefas perigosas, minimizando lesões no local de trabalho. Além disso, são programáveis e podem ser personalizados para atender a requisitos específicos de produção. Esta tecnologia de automação reduz os custos operacionais e aumenta a produtividade, tornando-a parte integrante das fundições modernas.